|

Mount Bauple Central

Mill Tramway

(Click here for more info on the 1907 Fowler)

MOUNT BAUPLE MILL TRAMWAYS (by J. Armstrong) Sugar production started in Queensland in 1862. During the two following decades, while the industry was in its infancy, the crushing of sweet juice from cane was carried out at many small privately owned "mills". The term is used in parenthesis, for many of these concerns were simply farmyard affairs, many of them used by the one grower for his own crop. In fact, some land-owners grew their own cane, crushed it and produced their own rather low-grade sugar. Others grew and crushed their cane and sent the juice for purification and crystallisation to "juice mills", or distilleries. According to Government statistics, there was a maximum of no fewer than 166 "mills" in operation in the years 1884 and 1885. Their average size can be judged when it is considered their overall average output per annum was less than 337 tons (342 tonnes). Today, 31 mills spread throughout the coastal belt of Queens-land process 16 million tonnes of cane to produce over two million tonnes of sugar.

The trend towards more economic and efficient crushing at larger mills commenced during the 1880's, by which time large amounts of capital were being in-vested in the sugar industry, and large plantations were being established. All cane grown on such estates was treated at an on-site mill operated by the plantation owners. A mill of this nature in areas where smaller farms were already or subsequently established often took on crushing for these farmers as circumstances permitted.

Pacific Islanders were indentured to provide labour to operate the larger estates, and though Kanaka labour had been used from as early as 1863, the heavier demand generated by the industry's expansion led to a shortage of volunteers which ultimately led to the notorious "black birding" which stains Queensland's history. A Royal Commission appointed in 1885 condemned the kidnapping and forced employment of islanders and compelled the Griffith Government .to enact legislation to abolish the importation of Polynesian labour after a five-year adjustment period. A petition drawn up by farmers in the Mackay district was presented to Parliament shortly afterwards seeking Government assistance to set up cane growing with white labour.

The Griffith Government, intent on keeping the sugar industry viable, allotted a large sum of money (e50,0001 to assist the formation of co-operative groups of farmers to plant and supply cane to specially erected district mills that formed part of the co-operative scheme. Thus began the Government sponsored Central Mill system.

The first two mills to be erected under this scheme were at North Eton and at Racecourse in the Mackay area. It was hoped at the time when they made their first crushing in 1888, that other already established millers would follow the move to more efficient methods of central milling, to overcome the labour problems created by the ban on Polynesians and a growing depression within the industry. Fourteen other mills that still operate to-day had already been established in one form or another at this time. They were Pleystowe (established in 1872), Rocky Point (1878), Fairymead (1879), Marian (1882), Millaquin (1882), Macknade (plantation established 1882), Victoria and Mourilyan (both crushed first in 1883), Farleigh and Hambledon (both established 1883), Kalamia (established 1882,

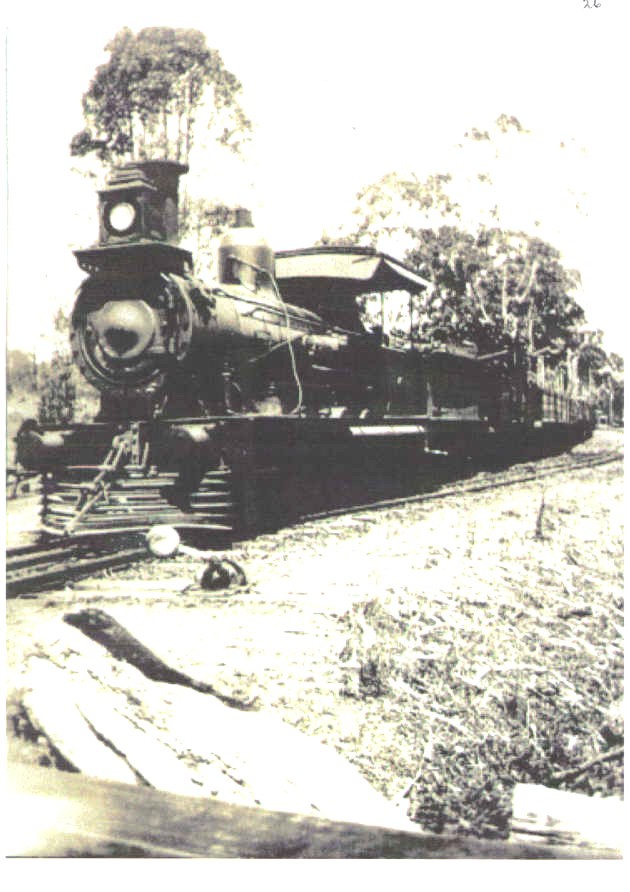

An early view of the Mount Bauple Central Mill showing both the Krauss and the B.12-class locomotive. (Photo: G. E. Bond Collection)

first crushed 1884), Pioneer (crushed 1884) Bingera and Goondi (both first crushed 1885). To them could be added the large Homebush mill which first crushed in 1885 but which closed in 1921. Ninety-one other mills did not last beyond 1920, however.

Further incentive to the Central Mill system was given under "The Sugar Works Guarantee Act of 1893" introduced by Sir' Thomas Mcllwraith, Griffith's successor as Premier following a change of government. This was a Bill to authorise loans from the Treasury for establishing approved sugar works, including purchase of machinery, and construction of mill tramways. Generous repayment terms were incorporated with the aim of assisting an industry still beset with grave labour problems.

The outcome was the erection of sugar mills at Nerang, Nambour (Moreton Central), Mount Bauple, (North) Isis, Wallaville (Gin Gin Central), Sarina (Plane Creek Central), Proserpine, Mulgrave and Mossman, whilst loans were also made to the already operating mills at Pleystowe and Marian, and to the Double Peak Central Sugar Company, a tramway consortium formed for the purpose of conveying cane to North Eton sugar mill. Mount Bauple Mount Bauple was the first mill of its kind in the Maryborough district where farmers had previously relied largely upon the refinery at Yengarie to distil their cane juice. Its inauguration was mainly through the efforts of a Mr. McKellar who became its first secretary.

A total amount of £32,480 ($64,960) was obtained from the Government under the Sugar Works Guarantee Act, and in 1895 a £27,500 ($55,000) tender by Walkers Ltd of Maryborough, the lowest of five tenders, for supply and erection of a complete milling plant was accepted. Work on the plant commenced immediately at the shareholders' request.

The site for the mill was at Turkey Creek about halfway between Gympie and Maryborough, and five miles east of the Government-owned Maryborough Railway which had been opened between these two settlements in 1881. This railway, now a part of the busy North Coastline, skirts low lying land around the western foot-hills of 1,627' high Mount Bauple. The site chosen for the mill was on the eastern slopes of the mound near a pocket of rich soil.

Crushing at the newly erected establishment commenced on 14th July, 18g6, and during the first season which followed, 10,314 tons (10,480 tonnes) of cane were rolled and 982 tons (998 tonnes) of sugar was produced. The product was bagged, as was the custom of the day, and was then hauled in horse drawn drays along the main road to Tiaro, about 6'/2 miles (10.5 km) north of Bauple, where it was transhipped into rail wagons.

An approach was made to the Commissioner for Railways at the end of the season to survey a rail route to Bauple, the company considering that it would benefit from construction of a tramline to Netherby, on the Government railway, to improve cane supplies. But the Commissioner considered that traffic potential was slight and advised the company instead to apply for assistance under the Sugar Works Act. As a result construction of a connection was postponed.

During the 1897-98 season, the mill started working night shifts and produced 1,232 tons (1,252 tonnes) of sugar from 12,011 tons (12,204 tonnes) of cane. Output increased for the next two seasons to a maximum of 2,219 tons (2,255 tonnes) of sugar.. However, as Dr. Walter Maxwell, Director of Sugar Experiment Stations for the Queensland Government, stated in a report, the mill was in fact capable of processing 4,000 tons a season, and was really working at half pace.

Lack of adequate transport facilities was a double edged problem, for not only was the method of getting sugar to the railhead slow and laborious, the means to get cane supplies to the mill was equally difficult, and as a result, crops along the railway line that the mill could have easily treated were sent elsewhere for processing. Short sections of 2' gauge tramlines were in use by 1897 using horse traction, but these served just a few farms close to the mill. Inevitably, the company was faced with financial difficulties.

In 1899, its directors approached the Divisional Board (forerunner of the Shire Council) seeking cooperation in a joint venture to seek money from the Government to build a rail connection to Bauple. An exhaustive report on the proposed route was prepared by that well-known engineer of the day, Mr. Geo. Phillips, C.E. However, the Board declined to give its support to the company, and the mill was forced to proceed on its own initiative. A deputation was sent to meet the Treasurer, Hon. R. Philp, who "promised to consider favourably any application through local authorities for a tramline loan".4 Thus, it appears, matters were back to the start again. The company was successful later in the year, however, of raising a loan of £3,000 ($6,000) for "improvements and extensions to the mill tramways."5 Government Control

A fall in production was experienced during the next two seasons, and in 1-902, severe drought reduced the annual output to a mere 133 tons. This, coupled with the mill's inaccessibility and resulting lack of adequate cane supplies, virtually led it to insolvency.

The Government was obliged to step in and from 1st January 1904, the Treasury took over its control. Dr. Maxwell, Director of the Sugar Experimental Stations and newly appointed Comptroller of Central Mills, took charge and appointed Mr. A.B. Martin to act as manager. Mount Bauple was not the only mill in this position —five others which had been originally financed by the Government were taken over about this time.

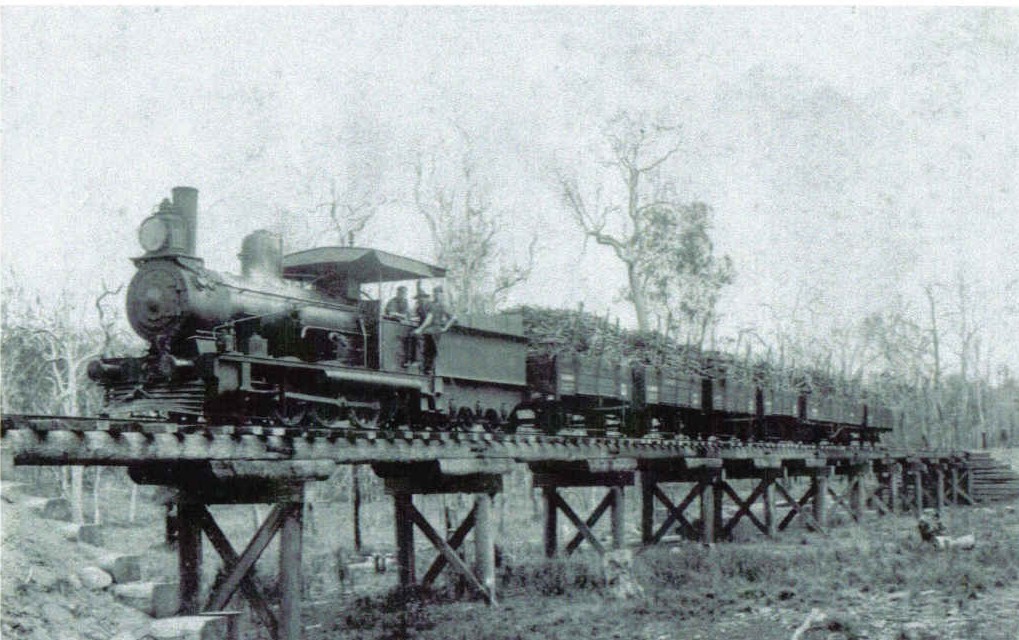

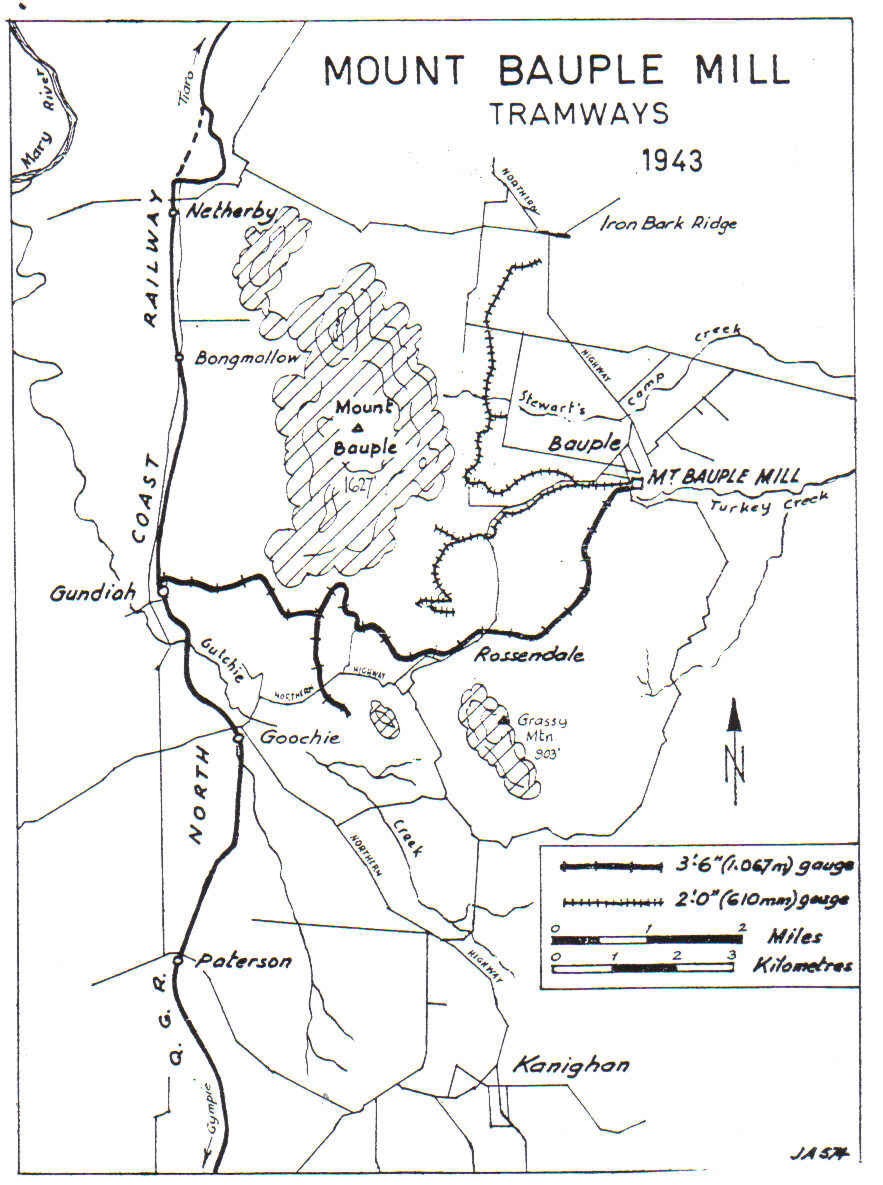

lthough Government intervention may have caused concern, it was to prove beneficial in one respect, for it gave each of them a voice within Government ranks. For Bauple, it proved to be more, because the next year it was decided to provide the necessary rail link to the mill. Gundiah-Bauple Tramway A 3'6" 0.067m/ gauge tramline was proposed to connect the mill with the North Coast Line at Gundiah. Supplies of cane grown beside that line which had been processed elsewhere previously were then to be channel-led over the new tramway to Bauple to ensure adequate supplies for the machinery. The sugar produced from this, and from local supplies, was then to be railed out over the same line and on to markets. It was estimated that the saving in cost of horse haulage to Tiaro would be equal to 5% interest upon the estimated cost of the tramline.6 The link, which was to be 6m45c. (10.5km) long, was first estimated to cost £7,474 ($14,948) but by 1907 this figure was revised. An additional £75 ($150) was included for alterations to the mill yard, which embraced shifting the weighbridge, and £200 ($400) was belatedly allowed for tools for construction of the line, which was to be arranged by the mill management. A survey was carried out in 1906 and plans were prepared. The Inspecting Engineer, Mr. W.E. Oesplace of the Bureau of Central Sugar Mills (who was also then acting as manager for the Moreton Central mill) reported in February, 3907, that the plans had been prepared and steel rails and other material had been received and were stacked in Gundiah yard. The maximum grade indicated was 1 in 41, but only for a "short distance"7. Construction commenced during that month and the line was opened for traffic at the beginning of October, 1907. Total cost amounted to £16,854/9/6d ($33,708,94), about e5,609 above the revised estimate. The huge increase was attributed to construction of an additional 35 chains of track, including a "substantial" bridge to carry the rails to the junction point finally decided upon by the Railway Commissioner. A short-age of skilled labour due to high pay being offered on new railway work "in the north" was also blamed, together with adverse weather conditions encountered during construction. It was admitted that cost of sleepers was about 50% more than anticipated The line was built to a 5-ton axleload standard using 41% lb per yard rails with sleepers spaced at 2'6" centres. Route The line left the northern end of Gundiah station yard in a right hand sweep, soon crossing a short timber trestle. It headed east for a mile, began to skirt the southern foothills of Mount Bauple, turning first south east then almost north, and then again followed a south easterly course to about the three mile. One mile further east, Rossendale was reached and the main northern road (now the Bruce Highway) was crossed on the level. The track continued eastwards a further half mile then turned north east for the climb to the mill yard. Sidings and Traffic In 1909, it was reported that a loading siding had been put in for cane at the Mount Bauple Range, the locality of this not being known to the writer. In 1910, a dividing siding was also laid in where the line climbed the foothills of the mountain. It was remarked that the tramline was providing the mill's salvation. Cane was now being transported in by rail from areas far removed from Bauple. Besides taking in cane from stations and sidings on the North Coast Line near Gundiah, supplies were being railed from as far away as Gympie (30 miles south of Gundiah), Biggenden on the Gayndah branch, 60 miles away, and from Kawungan on the Plalba-Urangan branch, also 60 miles distant. Some timber was also being carried over the line to Gundiah, and two loading stages for this traffic were erected during the year in the mill yard.7. Extension Towards Kanighan Complaints had been made on many occasions by growers in the Kanighan district six miles south of the mill regarding lack of adequate transport, and as a result, an extension to this area was promised. A 2m. 8c. (3.4km) survey commencing from a point 5 miles (8km) from the mill and near the dividing siding was commenced in a southerly direction, in April, 1911.8 The survey took the line to within 3 miles of the district. Work on the formation commenced during the 1912 slack season, and rails were laid and the ex-tension was completed the following year to that point.7

However, it was never completed to Kanighan. It appears no firm agreement to supply cane if the track was laid was reached between Kanighan district farmersand mill management, and much of the land was given over to dairying rather than cane-growing. It was observ-ed by one contemporary correspondent that the area was in any case subject to heavy frosts, and the project seems to have had doubtful value. Developments and Changes Due to the unsuitability of timber used for sleepers on the main tramway and because of the original wide spacing, opportunity was taken in the 1912 slack season to resleeper curves and respace them at 2' centres. The remainder of the line received similar attention in 1915.

The mill's fortunes still fluctuated: in 1912 it crushed 24,378 tons (24,769 tonnes) of cane but in 1919 it did not crush at all. In 1924, as a result of an anticipated increase of cane supplies it was reported that additions were being made to the mill plant, and increased siding accommodation was provided on the tramline.7

Perhaps the best, and certainly the most productive year during the period the mill was under Government control occurred in the 1926 season, when 46,774 tons (47,525 tonnes) were crushed. Of this, 26,949 tons (27,381 tonnes), or 56% of the total, was transported to the mill via the 3'6" line. This season saw a surplus of cane being available for the first time, and 8,000 tons (8,128 tonnes) of it was diverted to Bingera mill and Gin Gin Central mill west of Bundaberg, because of local shortages in that area.

However, at the close of the following season, the Treasurer announced that the Government intended to cease operating North Eton, Gin Gin and Mount Bauple mills due to continuing unsatisfactory financial results. Arrangements were subsequently made for the management and control of each mill to be vested in their respective suppliers, and under the terms of "The Primary Producers' Co-operative Association Acts 1923 to 1926" and subsequent legislation, they formed them-selves into co-operatives in order to continue operations. Boucle continued cc such co-operative through the 1930's and 1940's, but continuing difficulties, and the necessity to replace aged and worn out machinery and lack of sufficient capital to do so, finally forced its eventual closure in 1950.

Since this time, cane has still been grown in the area, and is now transported to the Maryborough Sugar Factory's mill at Maryborough, using piggyback road transport. Locomotives and Rolling Stock At first, the mill management hired locomotives and rolling stock as needed from the Queensland Railways, probably the most sensible thing to do considering the seasonal nature of traffic and the fluctuations each season.

The largest engines available for hire within the Gundiah tramway's permissible axleload were the B12-class, which, with a 2-6-0 wheel arrangement and small driving wheels, were suitable for the job required. It would seem one engine was hired at a time, and that different locomotives ran to Bauple at various times. However, at least one Al2-class 4-4-0 engine, No. 62, was hired — either during poor seasons, or in earlier years. Though it was less suitable for hauling traffic up the range, its lower hire charge would have been attractive, and the dividing siding was available. No. 62 was built in 1882 at the Philadelphia Works of the Baldwin Locomotive Co., U.S.A. It was the class leader of what was first called the "American Passenger" type locomotive, later the Al2-class, and closely resembled its larger standard gauge American contemporaries.

Cylinders were 12" diameter by 18" stroke, driving wheels were 48" diameter, and the boiler originally carried a pressure of 120 p.s.i. By the time No. 62 came to the Gundiah-Bauple Tramway, it had been re-boilered like others of its class and carried 140 lbs. working pressure. This gave it a rated tractive effort at 80% pressure of 6,048 lbs. In fact, this was one of the two engines that featured in unfortunate boiler explosions at Roma Street in 1898 (see Bn. No. 369 —July, 1968). It was finally written off in September, 1923.

One of the B12-class engines hired was No. 30, which was eventually purchased by the mill in May, 1926. It had been built in England by Kitson and Co. (works No. 2044) in 1875, and had 12" diameter by 20" stroke cylinders, 39" driving wheels and weighed, with 6-wheel tender, about 32 tons. It carried a boiler pressure of 140 p.s.i. (originally 120 lbs.) and tractive force at 80% was 8,270 lbs.

It had seen service since 1876 on the Southern and Western Railway (which then extended from Ipswich to Dalby, Warwick and Brisbane), was used to assist construction of the link between Gladstone and Bundaberg, and had apparently been used on further construction work between August, 1911 and August, 1912, during which period it was under the control of the Chief (Civil) Engineer for Railways.

In 1917, it took part in an interesting but unsuccessful test up the Toowoomba Range on 6th September, when it was coupled with P615-class locomotive No. 559 that had been temporarily modified so that it could supply steam to one of No. 30's cylinders as well as its own two.

When it entered service, it had a four-wheel tender In 1879, it exchanged it for a 6-wheel 1,000-gallon capacity type. By the time it ended its days, it was hauling the tender originally fitted to 1312 No. 34 which had been built at Ipswich in 1878. The tender still carried a builder's plate bearing works No. 2 when it was sold to the mill. When the tender was fitted to the engine is speculative.

It was named "Bauple" after purchase and was fitted with cast plates that were mounted on the boiler cladding. However, it retained its other builders' and number plates.

It remained the sole 3'6" gauge locomotive owned by the mill company. As axleload permitted on the Gundiah tramway was only 5 tons, the types of wagons run never it were res restricted to small 4 and 8-wheel types such as the F, Dr, H and S of the Government fleet. The writer has not been able to ascertain whether the mill owned any 3'6" gauge wagons of its own. Photographic evidence suggests that Queensland Railways' stock was used exclusively. 2' Gauge Tramlines Although the Gundiah line had taken more than a decade to appear, Bauple mill started using tramlines for cane transport in 1897, its second season of opera-tion. Two miles of 2' gauge portable track and 70 trucks were purchased.

The wagons were horse drawn and although the system worked fairly well, it was found that portable tracks were not robust enough for the work of conveying supplies into the mill. It was therefore decided to lay permanent main lines. It was reported that there were 3% miles of permanent track and 3 miles of portable tramlines in use in 1898.7 The latter were retained, of course, for use in the field. The number of cane trucks had been increased to 110 by that year, and they were supplemented by a further 40 the following year.

Because of the financial plight of the establishment, few improvements to the tramway were made. In fact, less than half the cane in the district was being transport-ed each season by rail, and in 1907 the number of trucks in use had fallen to 80. The greater proportion of sup-plies was carried in stacks lengthways on antiquated horse-drawn German wagons, and had to be unloaded by hand.

In connection with construction of the Gundiah-Bauple line, re-arrangements were made in the mill yard, a 2' gauge line for empty trucks was laid, and sidings were put in under the filter press. Doubtless this was to enable filter mud to be carried away in rail wagons, it being a commonly used fertilizer for a number of years.

A total of 100 trucks were then back in use. Thirteen more were built at the mill for the following season, and ironwork for 100 wagons was purchased in 1911-12.

A further re-arrangement of lines in the mill yard took place in 1912-13, extra sidings were laid and a small 2' gauge steam locomotive was purchased to re-place horse traction on the main lines. This was an 0-4-0 well type tank engine built by Krauss and Co. of Munich, obtained through Wilson Burton Ltd., sub-agents for Krauss' Australian representatives, Dierck and Son of Melbourne.

Typical of the Krauss products of the time for very light work, it carried works No. 6611 of 1912. It had 180 mm diameter by 300 mm stroke cylinders (approximately 7 1/8" x 12"), 610 mm (24") diameter driving wheels spaced at 1,100 mm centres, and measured 4,050 mm over frames. Height to the top of its diamond shaped chimney was 3,000mm. Dimensions in the accompanying diagram are given in imperial aquivalents. The boiler pressure of 190 p.s.i. gave a rated tractive effort at 75% working pressure of 3,617 lbs. Its working weight was about 5 tons.

With its acquisition, plans to extend the narrow gauge tramlines were put into effect, and the engine went to work shortly after its arrival in September, 1913 on construction of a 2 m. 20 c. (3.6 km) long line to Beaumont, north east of the mill.

The effect of the extension was that in the following season two thirds of cane supplies were obtained from local growers by rail. Purchase of the locomotive, the manager reported, reduced haulage costs from 15 pence to 5.7 pence per ton. 24,378 tons (24,769 tonnes) of cane were crushed that season.7

The tramways eventually grew to a length of about 10 miles (16 km), rather small by to-day's average mill tramway extent, but an asset to the small pocket of canelands surrounding Bauple mill. There were two principal lines, each with small spurs off them.

All railway lines ran west from the mill, including the Gundiah line, which ran beside the 2' gauge track for about 15 chains (300 metres) before they parted company. The 2' line continued west for about a half mile (800 metres) then divided into two at a simple junction. The longer Beaumont line ran towards Mount Bauple's foothills, then turned north and crossed Stewart's Camp Creek to terminate in the Iron Bark Ridge area about 4 miles (6.4 km) from the junction, at a point about a mile beyond the original Beaumont terminus. The lino had been extended this far in 1924.

The other line followed the main road for more than a mile in a south westerly direction from the junction, then crossed it to serve canefields on the south eastern slopes of the mountain. Its length is judged to have been about 21/2 miles (4 km).

As the writer did not have an opportunity to see the tramlines in operation he cannot give any details of sidings or notable features of the various lines. Traffic operations must have been necessarily simple, as only one locomotive operated on each gauge. It is known that trains had to divide on the Gundiah Tramway, otherwise operations seem to have failed to attract attention. Portable 2' gauge tracks were used in the field during harvesting as was the case at most other mills. Closure Though it was to operate for 54 years, the mill seem-ed to be dogged by bad luck, at times by poor manage-ment, and it certainly suffered from lack of capital. It was also established in an area of limited potential so far as frost-free cane growing was concerned, and the absence of adequate transport facilities to connect it with the outside world until the Gundiah Tramway was com-pleted in 1907, gave it a bad start.

Due to financial difficulties operating the works in earlier years, growers were not paid what they considered their just dues for cane they grew and supplied, and this led to much dissatisfaction, culminating in a test case held in the Maryborough Supreme Court in April. 1910, in which judgement was given in favour of a grow-er in a claim for payment of cane at an adequate price. It was stated that it was the first of 53 such claims for breach of contract in connection with cane prices promised by the Comptroller of Central Sugar Mills.8 Further trouble followed in 1911 when a sugar workers' strike highlighted unsatisfactory conditions at the mill.

Other factors did not help. The decision to build a line to Kanighan seems to have been a bad mistake, for better cane supplies were available north of the mill, in the opposite direction. As mentioned before, no firm agreement was even reached with the Kanighan farmers to grow cane.

When the mill was formed into a cooperative society at the conclusion of the 1927 season, growers in the Mary Valley began sending their cane to Moreton Central Mill. Depression was looming, and prospects for the local farmer shareholders were not bright.

Although it survived the 1930's it lost its Piabla cane to the Maryborough sugar factory, in 1939. After the second world war, a Committee of Inquiry into its business was set up by the Government in February, 1945. The report showed that in allowing the growers to take over the mill, it was necessary for the Government to write off the sum of 4121,266/19/8d ($242,532.98) to allow growers to take it over with a liability of£20,000 ($40,000) and that its indebtedness at December, 1944 was €21,955 ($43,910). It found that amongst the reasons for its shaky financial position was its very location and the high cost of transport. Over 45% of cane supplies came from the Miongar-terra area, over 24 miles from the mill, while in the immediately adjacent cane areas, six miles of the 2' tramway system was maintained for an annual supply of only 500 tons of cane. Lack of a progressive general policy came in for criticism. In 1947, the B12 engine "Bauple" travelled over Government metals again for an overhaul at the Brisbane works of Evans, Deakin and Co. It was the last overhaul it was to receive. By 1950, it had become apparent that the rundown plant at the mill could not last much longer without major overhaul, updating, and/or replacement. The decision, therefore, had to be made to finally close the mill at the conclusion of the season. The plant was placed on sale and subsequently re-moved, so that to-day the signs of the former district investment are difficult to see. The B12 engine was bought by scrap merchant J.J. Bloomer and was removed from the mill site and pre-sumably cut up, so that to-day only some of the plates from the engine remain. The Krauss locomotive was sold to Abrahams and Williams, another scrap metal firm, which, after removing the non ferrous metal from the machine on the site, left the rest of it there to quietly rust away. Conclusion and Acknowledgements

Although this article is not a complete history of the Bauple Mill and its tramways, the writer has felt that what is known of it should be published while there are still people around who may remember its operations. Perhaps it may lead to discovery of important facts not yet published.

The encouragement and assistance of Messrs. G.E. Bond, D.G. Bailey, W.E. Henderson. J.D. Kerr, and D. Sheehan with some of the historical information and photographs used is gratefully acknowledged. From Mr. J.W. Knowles' excellent article on that legendary 19th century engineer, Geo. Phillips, C.E. (8n. No. 392 -- June, 1970) came the information that he had been involved With the Gundiah Tramway. Other references have come from papers in the Oxley Memorial Library, Brisbane, to which acknowledgement is extend-ed. These include reports of mill managers appointed during the period that it was controlled by the Govern-ment. Some other specific references are indicated below: 1. Sugar Journal and Tropical Cultivator, May, 1895. 2. Votes and Proceedings and/or Queensland Parlia-mentary papers, various years. 3. Report on Central Sugar Mills by Dr. W. Maxwell 1904. 4. Sugar Journal and Tropical Cultivator. February, 1900. 5. The Queenslander, 18th February, 1899. 6. Votes and Proceedings, 1905. 7. Annual reports (various) by mill manager, pub-lished in Queensland Parliamentary papers. 8. The Australian Sugar Journal, issues of June, 1910 and April, 1911. THE AUSTRALIAN RAILWAY HISTORICAL SOCIETY (Founded 1933) AFFILIATIONS: The New Zealand Railway and Locomotive Society, The Australian Electric Traction Association, The Railway Correspondence and Travel Society (England), National Railway Historical Society, Incorporated, of U.S.A., Stephenson Locomotive Society (U.K.), Irish Railway Record Society (Eire), The Railway Society of Southern Africa, Canadian Railroad Historical Association, Light Railway Transport (U.K.), Light Railway Research Society of Australia, Narrow Gauge Railway Society (U.K.). BULLETIN EDITOR: I.K. Winney, 89 Cliff Road, E

|